磁粉检测是无损检测方法的一种,目的是检测表面和近表面缺陷。其检测对象是铁磁性材料。金属分为铁磁性材料,顺磁性材料,非磁性材料。只有铁磁性材料才能有效的采用磁粉检测方法。

磁粉检测原理

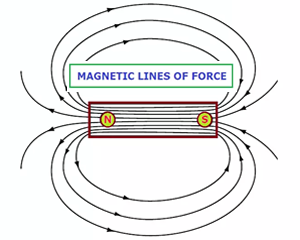

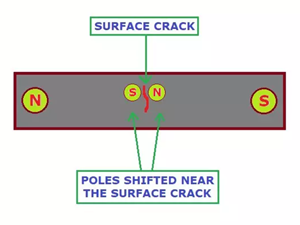

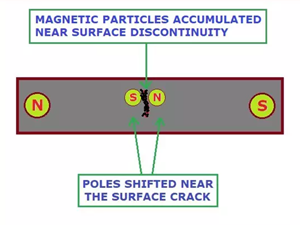

该方法使用磁现象,当磁体发生表面断裂时,磁力线的路径会中断。任何磁体都有两极,即一端的北极,另一端的南极。磁力线(也称为磁通量)从北极向南极移动(图1所示)。 表面的不连续性会使连续的磁力线产生断裂,我们称为漏磁。在漏磁区会产生新的南极北极(图2所示)。 当铁磁性磁粉粒子,喷砂在磁铁上,它们聚集在磁极上。当有不连续性存在,漏磁的出现也会,使磁粉粒子聚集在不连续处。磁粉粒子在不连续处的聚集会产生明显的磁痕(图3所示)。

Magnetic Particle Testing (MT) (also known as magnetic particle inspection – MPI) is a non destructive test (NDT) method, used to detect surface and subsurface (near to surface) discontinuities. This NDT method can be used on metals which can be easily magnetized (ferromagnetic). Metals can be classified as ferromagnetic, paramagnetic, or diamagnetic. Only ferromagnetic metals can be effectively inspected by Magnetic Particle Testing.

Principle of MT

This method uses the phenomenon of a magnet by virtue of which path of magnetic lines of force gets disrupted when a surface breaking is occurred in the path. Any magnet has two poles i.e. north pole at one end and south pole at the other. Magnetic lines of force (also known as magnetic flux) travel from north pole to the south pole, as shown in the below figure (Fig. 1). If there is any distinct change in the continuity (such as surface discontinuity) of magnet, then the magnetic lines of force will get distorted, this phenomenon is known as flux leakage. During flux leakage, additional North and South poles will be created near discontinuity (Fig. 2). When fine Iron particle (ferromagnetic particle) is spread over a magnet, it gets accumulated at the poles. But in case of any discontinuity, flux leakage would occur and the Iron powder will accumulate at the discontinuity, as shown in Fig. 3. The accumulation of iron particle at the discontinuity would produce a visible indication of that discontinuity.

磁粉粒子也称之为检测粒子。这些粒子可以是干形式,也可以与液体混合成悬浮液。液体可以是水或者轻质油。根据检测方式可以分为两类。

1. 着色磁粉。 着色磁粉,在白光环境下显示红色或黑色。

2. 荧光磁粉。 荧光磁粉,在黑暗中散发黄绿色的光。

提供磁场的几种方式

1. 电磁轭

2. 永久磁铁

3. 触头法

4. 线圈法

磁轭,通常是交流磁轭,其方便与快捷。并且磁轭两腿距离也可以调节,且产生纵向磁场,要求检查过程中,两次交叉检测。

触头法和线圈法也常被用来作为产生磁场的工具,但是触头法容易产生电打火形成表面的损伤。线圈法适用于长条形工件。

Particles used for Magnetic particle testing is similar to ferromagnetic particle and is called as detection media. These particles may be applied in dry form or may be mixed with liquid and spread over the area where Magnetic particle test has to be performed. Liquid like kerosene or a similar petroleum distillate may be used. Water can also be used by using suitable additives such as wetting agents and antifoam liquids. To provide better contrast with the test objects and enhanced sensitivity, these particles are coated, there are two types of coating;

1. Color contrast coating.Color contrast coating: Color contrast coatings are available in several colors such as red, black etc. Color of particle are selected so as to provide a good contrast with test object.

2. Fluorescent coating.Fluorescent coating: Fluorescent particles can be seen under a ‘Black light illumination’. These particles emit light when seen by a black light in a dark background. These particles provide excellent contrast in dark background.

To carry out Magnetic Particle Testing we need to temporarily magnetize the test object. Magnetization should be temporary in nature. To magnetize the test piece, common instruments which are used are;

1. Electromagnetic yoke

2. Permanent Magnet

3. Prod

4. Coil

Electromagnetic Yokes (Figure – 4)are also called as AC yokes, it’s very portable and commonly used in Industries. Yokes are connected with AC power source (Battery pack version is also available). Many yokes come with adjusting legs, to facilitate wide range of area profiles. These yokes produce longitudinal magnetization. Hence, for complete inspection, re-positioning of yokes in at least two 900 opposing direction is required.

Prod and coil method is also used for temporarily magnetizing the test object. Prods require good contact with test object otherwise it can damage the test object, due to electrical arcing. Coil method used to longitudinal product.

在检测之前,磁轭通常用八角试块或A型试片来验证磁粉方向。

磁粉检测按照如下步骤:

- 磁化工件

- 施加悬浮液

- 在相应的检测环境下进行检测

多种技术可以被前两步所采用,例如:湿法连续法。 检验介质应为具有高导磁率和低顽磁性的细铁磁粉,其尺寸和形状必须易于形成磁痕,磁粉粒度尺寸为 (供应商应提供磁粉颗粒大小的证明),磁粉的颜色应为黑色。磁悬液中磁粉的载体是油。

Before inspection, the yoke shall be properly checked by the flux direction indicators. The most common flux direction indicator used in the industries is ‘A Pie Gauge’. Other flux direction indicators are A Burmah Castrol strips and Quantitative quality indicator (QQI).

To carry out Magnetic Particle Testing, we need to follow the following activities:

- Temporarily magnetize the test object

- Suspend (spread) the magnetic particles (either dry or wet) on the test object

- Inspection of test object either by black light (in case of wet fluorescent particle) in a dark area or inspection in sufficient light (in case of color particle).

Various techniques are available to carry out the first two steps (mentioned above), these are:

Wet Continuous: Particles are mixed with liquid and suspended on the test area, magnetization of test area and suspension of wet particles shall be done simultaneously. Liquids such as kerosene or petroleum distillates can be used for this purpose. Kerosene and petroleum distillates are costly, highly inflammable and possesses safety related issues. However, water is inexpensive, available in abundance and possesses no safety related issues, but it can initiate corrosion in the test object.

鲁公网安备 37020602000203号

鲁公网安备 37020602000203号